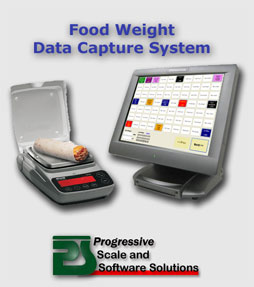

Taco

Bell Weight Capture System: Taco

Bell Weight Capture System:

This system was designed for use in fast food

establishments that want to keep track of weight data. Using

a web interface, the client is able to control, menus and report

on data collected from many extablishments. The rugged touch

screen computer is restaurant hardened and the scale comes with

a full flip down cover to protect it when not in use. This fast

food check weighing system is also sound enabled giving the

operator audio feedback whenever a transaction is recorded.

Color coded screens flash to the operator to notify them of

weight status for each transaction. A server application sends

out email on a selectable basis notifying corporate and stores

of their transaction averages and totals.

Bitterant

Addition System: Bitterant

Addition System:

Client: Anti-Freeze Manufacturer

System: Due to new goverment regulations, this very large Anti-Freeze

manufacturer was forced to add bitterant to its products to

keep it from tasting sweet which has led to accidental animal

deaths. The product used to make the Anti-Freeze taste bitter

is a very unfriendly substance. The manufacturer needed to handle

it as little as possible. Progressive was commissioned to build

a weight based automated bitterant filling and delivery system.

The system worked so well that the batch master coined progressive

the "True Rocket Scientists"

Meat Distribution Software:

Client:Meat and Poultry Distributor in California

Goal: The client needed a meat distribution software that could

Create Track and Invoice all incoming and outgoing meat items

using the Provision Processing System Packaged Software. The

client was using a hand written system to track orders and was

having some issues with tracking inventory properly. Using the

wireless bar code capability in the food processing software

provided, the client was able to accurately track their daily

transactions and send all transactions to Quickbooks.

Fish Processing Plant Software:

Client: Large Fish Processing Plant, Boston MA and New Bedford

MA.

Goal: Collect Scale information to a database from 2 plants

simultaneously, label cases with bar codes, handle barcodes

with a wireless windows mobile device and push the information

to a web based SQL server for management.

Technologies: Progressive used the Rice Lake 920i's programmable

scale in each plant connected to Zebra Label Printers to collect

weight data and print labels. Using the nearly indestructible

Wireless Datalogic Falcon Windows Mobile barcode scanner, case

labels are scanned against orders and weight tickets are automatically

generated. All information is then sent to a web based MS SQL

database where management can report and print reports from

the resulting data. All data is synced between the Boston and

New Bedford Plants.

Pharmaceutical Scale and Balance System:

A division of Johnson and Johnson recently contacted Progressive

to build a custom system to track batching for a pharmaceutical

application. Phase 1 has already been installed and we are working

on phase 2. Phase 1 involves multiple scales batching by both

weight and volume using a measuring sensor. The measuring sensor

was used as a load cell alternative to reduce the need for placing

load cells at the bottom of every tank. Weight was calculated

using volume and density.

Food Processing Scale and Software System

A NJ area lamb processor needed a scale and software system

to collect data at their lamb weighing stations. Progressive

provided a SQL based system for both SKU recall and data collection

as well as a bar code label printing. This lamb processing system

has given the lamb processor the ability to go after new clients

because of their new traceability, and label compliance abilities. See Provision Processing System

Truck Scale Software System

H. Krevit manufacturing of North Haven CT, a manufacturer of bleaches

and caustics, contacted Progressive for a truck scale system

capable of bar code scanner integration and controls, weight

to gallon conversion, data collection and assuring the right chemicals

go in the right trucks. After installation of the truck scale

and controls, Krevit saw a huge ROI. Now that

the system is installed and running, the truck filling system

saves as much as 1/2 hour per truck and is accurate to 2-3 gallons.

Caviar Processing System, Canada

A client contacted us in need of a Herring Fish Processing Software

and Scale System. The time frame was very short, but Progressive

came through. This processor pays workers by weight so the fish

system needed to collect each weight as well as employee IDs.

The system involved 3 networked scales and an SQL database.

The main benefits are time savings, accuracy of data and integrated

Crystal Reports.

Scale Calibration System

Well we just launched freeware software for scale companies.

It is called X-Calibar and it is a scale calibration software system. Designed to be a little

more simple than say the certificate retrieval system from Rice

Lake. This software should work for most small to mid scale

companies. If you are in the market for custom projects,

maybe next time you will give us a shot.

Automated

Bar Code Scanning Validation. United States Surgical

- May 2007. In order to make sure every suture is bar coded

properly, United States Surgical Corporation called in Progressive

Software Solutions. At 1/5th the cost of the nearest competitor,

Progressive built an automated bar code scanning system. Using

2 Symbol bar code scanners, 1 photo eye and a logic controller,

the system validates 2 bar codes against each other and rejects

any invalid scans. Automated

Bar Code Scanning Validation. United States Surgical

- May 2007. In order to make sure every suture is bar coded

properly, United States Surgical Corporation called in Progressive

Software Solutions. At 1/5th the cost of the nearest competitor,

Progressive built an automated bar code scanning system. Using

2 Symbol bar code scanners, 1 photo eye and a logic controller,

the system validates 2 bar codes against each other and rejects

any invalid scans.

Counting

and Labeling Scale System - The world's largest switch

manufacturer contacted PSS to see if we could develop a networked

counting scale that prints bar code labels to replace their pricey

Intermec fixed station terminals. PSS got to work and developed

a system that allows the client to connect to scales in Mexico,

TX, CT, England and China all from an IT desktop at HQ. Scales

can be programmed and monitored remotely all from the comfort

of the IT director's office. Counting

and Labeling Scale System - The world's largest switch

manufacturer contacted PSS to see if we could develop a networked

counting scale that prints bar code labels to replace their pricey

Intermec fixed station terminals. PSS got to work and developed

a system that allows the client to connect to scales in Mexico,

TX, CT, England and China all from an IT desktop at HQ. Scales

can be programmed and monitored remotely all from the comfort

of the IT director's office.

In Motion Check Weighing - Washington.

A reseller contacted us asking if we could duplicate a program

for a Rice Lake 920i that they had been buying elsewhere. PSS

took the challenge and built the system. To the client's amazement,

the system is far more accurate than the previous system making

it easy for the reseller to beat out its competition. In some

cases, the reseller is installing the in motion check weigher

on competitive set ups that use the same scale indicator. Clients

are thrilled with the accuracy increase.

Cross

Dock Barcode System - Waterbury, CT. ITW, one of the

largest manufacturing companies in the US, asked PSS to build

them a cross dock wireless bar code system. The system uses

Intermec wireless units to verify skidded boxes against an AS-400

database. As a result of scanning, master labels are produced

for skids. To the client's amazement, the bar code system found

errors on the first day of operation. Cross

Dock Barcode System - Waterbury, CT. ITW, one of the

largest manufacturing companies in the US, asked PSS to build

them a cross dock wireless bar code system. The system uses

Intermec wireless units to verify skidded boxes against an AS-400

database. As a result of scanning, master labels are produced

for skids. To the client's amazement, the bar code system found

errors on the first day of operation.

Automated

Box Weight Filling System - Greenville , SC. A local

scale dealer called in Progressive to pick up a project that

the scale manufacturer did not complete to the client's satisfaction. Each

box was filling to nearly 1/2 lb over target. A

loss of nearly $300/hr. After consulting with the customer,

Progressive devised a new program that would auto learn the

product fill rate. Progressive completed the project within

3 days time and now fills exactly to target with 0 loss. Process

includes automated box placement, automated filling, and automated

box removal. Automated

Box Weight Filling System - Greenville , SC. A local

scale dealer called in Progressive to pick up a project that

the scale manufacturer did not complete to the client's satisfaction. Each

box was filling to nearly 1/2 lb over target. A

loss of nearly $300/hr. After consulting with the customer,

Progressive devised a new program that would auto learn the

product fill rate. Progressive completed the project within

3 days time and now fills exactly to target with 0 loss. Process

includes automated box placement, automated filling, and automated

box removal.

UAS4000

Labeling Counting Scale - A

fully functional Rice Lake 920i based counting scale package

capable of part number, UW and 5 additional fields storage.

Unlimited label designs that you create. PC Integration. Bar

Code Scanner Integration. Network integration and more. The

UAS4000 far exceeds any counting scale system on the market today

and implements all the functions that clients have been looking

for in their counting scales but were up until now unable to

acquire, and it's American made. Over 35 0f these programs are

currently running without fail in multiple facilities. Demos

are available for this product. UAS4000

Labeling Counting Scale - A

fully functional Rice Lake 920i based counting scale package

capable of part number, UW and 5 additional fields storage.

Unlimited label designs that you create. PC Integration. Bar

Code Scanner Integration. Network integration and more. The

UAS4000 far exceeds any counting scale system on the market today

and implements all the functions that clients have been looking

for in their counting scales but were up until now unable to

acquire, and it's American made. Over 35 0f these programs are

currently running without fail in multiple facilities. Demos

are available for this product.

Soft

Indicator - In response to many of the scale distributors

we work with we designed a PC based indicator package that works

with most scale indicators that have bi-directional RS-232.

The soft indicator collects data, prints labels, prints forms,

controls the scale and more. Demos are available for this product. Soft

Indicator - In response to many of the scale distributors

we work with we designed a PC based indicator package that works

with most scale indicators that have bi-directional RS-232.

The soft indicator collects data, prints labels, prints forms,

controls the scale and more. Demos are available for this product.

AS400

to Counting Scale - June 2006. Through a scale distributor

in the Northeast, PSS was able to assist in the winning of a

contract for a beta site of 4 Rice Lake 920i programmable scales

attached to their AS-400. Each scale pulls in job and average

piece weight data, customer data and label format data. The

system then controls a feeder and stops the feeder when a box

is full. The system then prints a label and logs this info and

sends the complete job info back to the AS-400 when complete. AS400

to Counting Scale - June 2006. Through a scale distributor

in the Northeast, PSS was able to assist in the winning of a

contract for a beta site of 4 Rice Lake 920i programmable scales

attached to their AS-400. Each scale pulls in job and average

piece weight data, customer data and label format data. The

system then controls a feeder and stops the feeder when a box

is full. The system then prints a label and logs this info and

sends the complete job info back to the AS-400 when complete.

Fiber

Bale Weighing and Labeling System Fiber

Bale Weighing and Labeling System

United Synthetics - Georgia

United needed a partner to help them track bales produced for

a particular PO and prevent over producing. United has 3 networked

920i scales tied to an SQL2005 server. Order data is entered

daily and operators make against open orders. The system also

labels each bale to comply with the customer labeling requirements.

The system handles partials and overrides for stock items.

New Enterprise Website Launch - June 2006. Haydon

Switch and Instrument (hsi-inc.com) is a world wide leader

in linear actuators, motors and switches. The people at PSS

were hired

to update their corporate

web site to include functionality that their engineers needed.

The new site now includes:

Intuitive Design • Outlook-like Menu Structure • Search • Product

Configurators • Database Driven Content • RSS News Feeds • Rep

Locators • Printable Pages • Email To a Friend • RFQ

Forms with Referring Pages • SEO (Search Engine Optimization) • Google

Marketing

Food Labeling Application - June 2006. A

Northeast based scale company asked us to design a labeling

system for a chicken processing plant it had been doing business

with for years. The current system from Digi (New Brunswick

International) was not being supported properly. Therefore we

set out to develop a chicken labeling system that was similar

yet easier to maintain. The new system utilizes a Rice Lake

920i and a Zebra label printer to print pricing labels for the

processor's grocery store clients. We had 2 days to develop this

system and it has been operational ever since.

Corn Flake Batching - April 2006. A Massachusetts based scale

company asked us to build a scale system for its client that

spoke

to a PC and pulled job data from an Access database and filled

totes accordingly then printed a tote label. The 2 systems

are currently

running

without

issue.

Large Scale Batching Application - April 2006.

A North Texas Scale Company hired us to help sell a client

on

a new

way of doing things as

their old equipment was no longer supportable. We closed the

deal together and delivered shortly thereafter. This system replaced

13 scale indicators and 1 programmable scale at the largest PVC

pipe extruder in the US. The new Rice Lake 920i system now

controls 16 scales and essentially

the

entire

24hr operation. The system processes approximately 150 batches

per day and has not once failed.

RF Bar Code System - A McKinney Texas based

manufacturer hired us to update their entire data collection

system. After carefully researching

the proper hardware and solution we gave a quotation to the

manufacturer. Time passed and one day the phone rang and it had

to be done "this week". We quickly did an Intermec site survey

one day and installed the next. Within 2 days their system was

up and operational.

Counting Scale Software System - May 2006

a NJ based scale manufacturer hired us to build a PC software

solution to work with

their counting scales. This solution is now distributed with

every scale sold. This solution was originally to be only a

data collection application but

was

finally delivered

with

multiple functionality such as

Label Printing • Database Sharing • Data Wedge

(where scale data goes into the cursor for any other Windows

application).

|